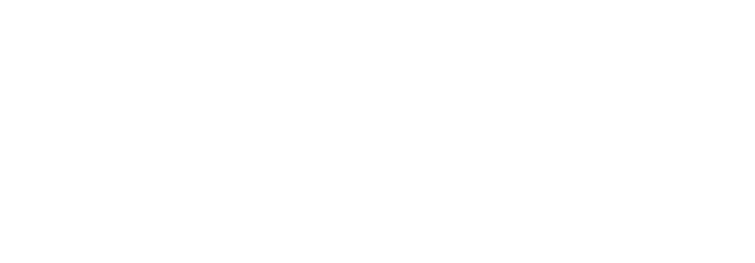

Family owned and operated in Ocoee Florida, we have four production facilities, each with distinct capabilities that we’ve added over our 40+ years to offer our clients full-service solutions.

About Us

350+

Skilled Team Members

110K+

Unique Designs in Production

200K+

Sq/Ft Production Space

Who We Are

Our Story

Hard work and honesty are the foundations from which Teak Isle was built. We started in 1979 as father and son driving hand-cut teak accessories to boat dealerships in the back of an old pickup truck. Providing quality products and old-school service led to additional opportunities, and when Wellcraft Boats wanted to outsource their teak fabrication they turned to the then-small team at Teak Isle to make it happen.

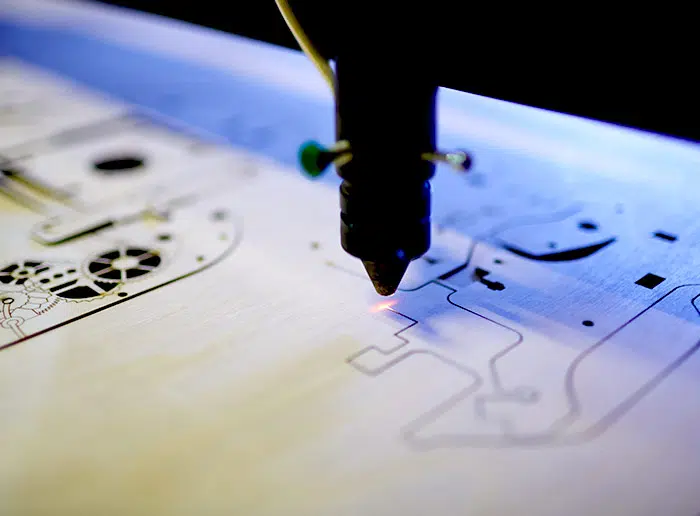

Relationship after relationship, new part after new part, over the next 40 years, we grew into the largest OEM supplier of CNC-fabricated marine parts in the country, serving well over 200 boat builder partners. We now have a team of over 350 employees (many of whom have been with us for decades) and loads of modern production equipment.

The majority of our early growth (and still largest category) is marine OEM — supplying component parts to major boat builders. The marine industry presents unique challenges, with a traditional ‘model year’ development schedule similar to the auto industry but operating at a much lower production volume. We custom engineer over 9,000 unique new designs each year. Each designed to withstand harsh marine conditions – UV rays, saltwater, 8-foot waves!

Our marine industry upbringing forced a standard of:

- Incredibly durable, high-quality products

- High-volume, innovative engineering

- Low MOQs and short lead times

- Long-term partnership approach to relationships

These core competencies, which have driven our success, have proven highly transferable and in demand beyond the marine industry. For projects where durability and quality are paramount and offshoring is not feasible, we are a perfect fit. We have active customers in industries including robotics, hospitality, medical, retail, military, and many more.

Small Enough to Care,

Big Enough to Deliver

As a multi-generation family business, every product we build & every relationship we establish is highly personal to us. You’re working with people fully invested in establishing successful long-term business relationships.

We look forward to the opportunity to earn your business.

Send us a Message

After hours or prefer to schedule a call? No problem.

Send us a message and we’ll jump right on it.

Call Us Now

Need a partner you can trust to deliver quality on-time parts?

Pick up the phone and chat with a team member now.

(833) 522-5090

Mon-Fri 8am – 4pm (EST)