Durable, weatherproof, and corrosion-resistant. Popular for outdoor furniture and marine accessories.

Our HDPE Fabrication Services

CNC machining is one of the most commonly used production manufacturing processes for creating complex, customizable, highly precise, and scalable parts. At Teak Isle, CNC machining is a foundational core competency with 12 state-of-the-art CNC routers. We have the infrastructure and experience to produce high-quality, custom components CNC cut to your specific needs.

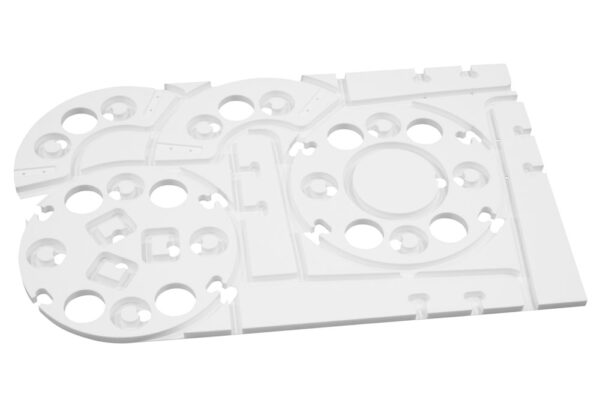

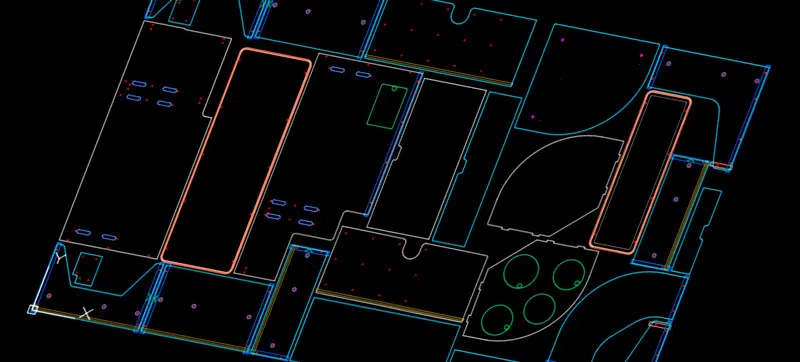

HDPE CNC Engineering

Our engineering team uses advanced nesting software to optimize sheet yield and determine the most cost-effective order multiples.

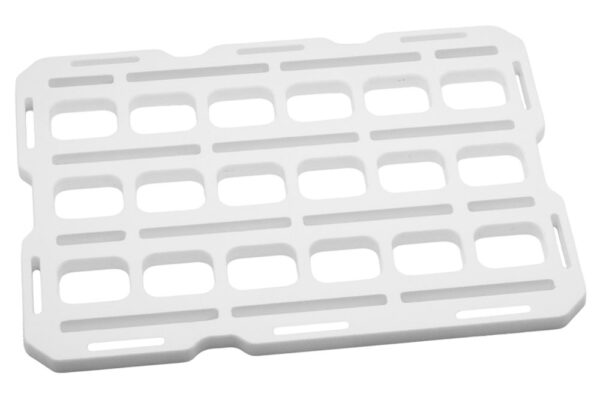

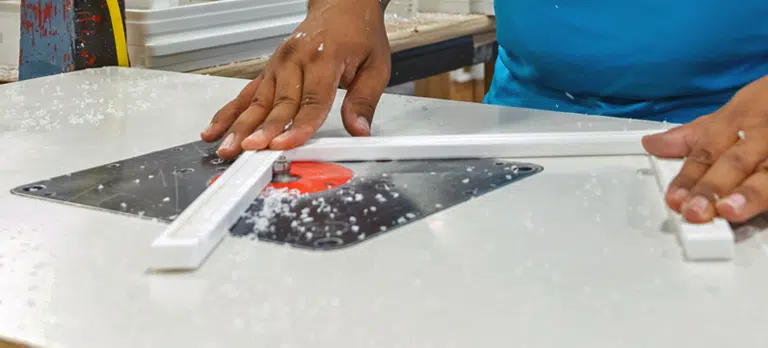

HDPE CNC Milling

We run 12 heavy-duty 3-axis CNC routers — guaranteeing quality accurate machined parts at the scale your business needs.

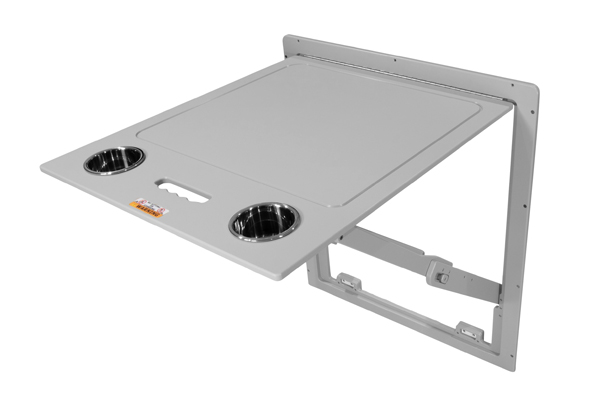

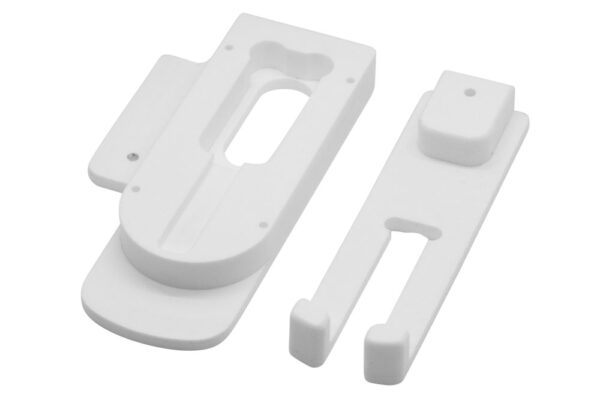

HDPE Finishing & Assembly

Post CNC Machining, we provide edge-routing, polishing, and assembly services to provide you with a ready to use finished part.

HDPE Fabrication 101

Advantages

- Versatility for diverse applications

- Long-lasting and low maintenance

- FDA-approved safety for food processing

- Resilient against corrosion and weather

- Easy processing and recyclability

Limitations

- Prone to expansion/contraction with temperature changes

- Challenging to bond with adhesives

- Relatively low stiffness compared to some other plastics

- Inability to paint directly; requires special treatment for adhesion

Common Applications

- Marine and boat components

- Outdoor furniture and playground equipment

- Cutting boards and food prep surfaces

- Exterior signage and displays

- Material handling & wear strips

Tradenames/Popular Brands

High Density Polyethylene, King StarBoard, SeaBoard

Sheet Thicknesses

.0625″ – 4″

.25″, .5″, .75″, 1″, 1.5″ most commonly available

Common Sheet Sizes

54″ x 96″

Custom sheet sizes up to 120″ available

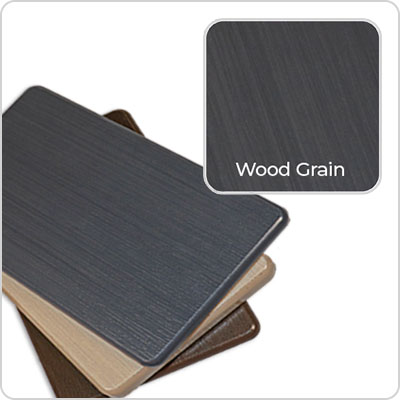

Preferred HDPE Material: King StarBoard

King StarBoard, renowned for its exceptional quality and durability, is our go-to HDPE sheet material. Designed for the harsh marine industry, it’s proven to hold up in the toughest environments, making it an excellent choice for diverse fabrication needs. We inventory King StarBoard in numerous colors and thicknesses – allowing us to provide you with King StarBoard component parts with low order minimums and without material commitments.

- Will not rust, delaminate, or rot when exposed to UV, humidity, or water.

- Superior sheet flatness and thickness consistency ensures reliable fabrication.

- Durable easily cleaned matte-textured surface on both sides.

Specialty HDPE Materials

Anti-Skid

Built-in texture for additional traction

Gallery of HDPE Fabricated Parts

Customer Success Stories

Teak Isle’s Low MOQs Helps HCB Yachts Offer the Customization Options Their Customers Demand

How Teak Isle Helps Godfrey Marine Turn Vision Into Reality and Improve Customers Time on the Water

An Extraordinary Commitment to Customer Service Drives Teak Isle’s Relationship with Everglades Boats

What they're saying...

Hear from our customers, and find out why Teak Isle is the best.

Send us a Message

After hours or prefer to schedule a call? No problem.

Send us a message and we’ll jump right on it.

Call Us Now

Need a partner you can trust to deliver quality on-time parts?

Pick up the phone and chat with a team member now.

(833) 522-5090

Mon-Fri 8am – 4pm (EST)